The producer brought curd in tubs or in bags from the farmers, from markets or from dairies home and weighed it for proper salting. In winter 3.5 to 4 kg of salt was used per 100 kg of curd, in summer – up to 5 kg. More salted cheese ripened slowly. Curd was lying for 1 – 3 days in low barrels, where it was mixed. When milling in a mill, salt was added after the first milling, more frequently after the second milling (4 runs were quite normal) to avoid pellet-like shape “.

Curd was originally processed by kneading. It was the most laborious step during the whole process of production. The most difficult and slow operation of kneading was used for small curd quantities only; curd treating by bare and well washed feet remained the most widespread original procedure. Two women or one man treated the 30 cm high layer of curd for one and a half or even for two hours. It is not quite clear, when the operation of curd kneading and foot treading was interrupted, but according to eyewitnesses it is documented in the 30s of the 20th century also in Luká and in Loštice.

The curd, not processed to the ripened tvaruzky within a few days, was stored in barrels or in concrete tanks. Holes were drilled in the barrels at the height of ca 20 cm from the bottom so that whey may be trained; the concrete tanks were equipped by grooved bars on the bottom enabling whey draining.

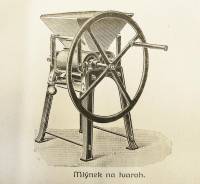

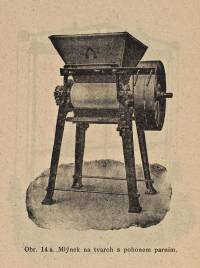

The whole process of curd processing was simplified and improved by using the curd mills; they were more and more popular from the late 19th and early 20th century. Mills often represented the only mechanization in small tvaruzky factories; the mills were based on two counter-rotating rollers. The mills were initially manual but, later on, they were usually electrically powered. Some producers claimed that „… the mill cannot replace feet …“, but technological progress could not be stopped. The mills had at first wooden and then granite or steel rollers; it was even possible to set the roller spacing or spring pressure on the roller. Spacing between the rollers was set, depending on the run of milling, i.e. the distance between the rollers was narrower during the next run of milling. Factory production of tvaruzky requested large mills and a scale.

The whole process of milling was equipped by a vat, tub or box (optionally on the wheels), where the milled curd fell down and, as shown in the specialized literature: „… at the bottom of the rollers there is a wooden or iron tinned knife to collect (scrape) curd … “. The scraper could be replaced by a steel wire, but again tinned, because the tvaruzky producer is convinced firmly that curd and iron may not be in contact during the process of production. Tinning and other production for the tvaruzky producers was ensured by the Richard Mittag tinsmith company in Loštice.

Curd had to be processed especially carefully for manual production, because in case of the later and the electric motor-driven moulding machines, curd was kneaded by the driving screw which pushed curd into the moulding machine.

If the curd was purchased for storing, it was milled and stuffed into barrels (in Loštice and in Hněvotín called ”štandle”) or into concrete tanks by a mallet, or more frequently by foot treading. The curd could even be stored outdoors, and if it has frozen, it was still usable for production in case of cautious handling. For further processing the freshly prepared and stored curd was mixed - mostly half and half; otherwise it remained loaded for the whole time period till further processing (mostly slabs loaded by stones or concrete blocks). When stored in tanks, whey was drained through special grooves in wooden bars on tank bottoms. For tvaruzky production the curd had to be processed until it was a „sticky dough“ and the producer did not feel any pellets “.

Kerosene lamps were at first used for lighting the production areas, acetylene lights were used sporadically, but everything has been changed by electricity at the beginning of the 20th century. In Loštice it was the city power plant in 1909.