World of cheese is opened

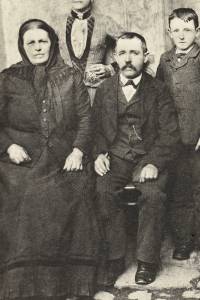

Josef Wessels was the first to produce the ripened curd cheese in Loštice in 1876, from 1898 his son Alois continued the business. Josef Wessels descendants are now the sole producers of the Olomouc cheese. The cheese is named after the famous markets, namely - the OLOMOUC markets. During nearly 20 years, until 1913, as many as 120 cooperative farmer dairies were established in Moravia and in 1913 they produced over 3,000 tons of curd. For the curd cheese producers it was an excellent opportunity, which was utilized best by Alois Wessels. He has opened the door to mass production and its curd cheese factory became the greatest of all.

Leporelo

1. A long journey.

„When you are passing the fence where the cows are grazing, stop. Cows will raise their heads and one by one will come to you to look closer. Are they waiting for something? Or are they simply attracted by high society? A long time ago I was thinking whether the animals have a mental life. I mean something more than instincts and habits.“ Written by Ludvik Vaculik in The Last Word, January 21 2014. L.Vaculík spent his childhood at the time when cows and goats were being pastured and the animals, especially cows, belonged to the family life. They had names and their premature death meant the same sadness as the death in the family. For thousands of years, the strong bond of the coexistence of animals and humans, which was extended far beyond the simple benefit of breeding the animals, has been created. From the middle of the 19th century the companies and associations which were taking care of domestic animals emerged, some communities held the big exhibitions of cattle and the medals won there were something like small Nobel Prize for the small farmers. Czech Economic Association in Loštice held a similar exhibition in 1895.

2. At the beginning was the milk.

Milk belonged to the daily routine and was the basis of home cheesemaking. When the milk acetifies, that is the first step of producing. In some parts of the world, more types of cheese began producing, such as the cheese in Haná. Most of the milk wasconsumed by households, but its remains like eggs and butter were being sold on the market. The home-made cheese was gradually getting to the markets, too. There were not a large amount of goods on the markets and income from the sales of the small remains from the markets was traditionally being kept by a housekeeper – especially for the clothes. Napoleon's armies affected the life in the 19th century across the whole Europe, from the Atlantic to Moscow. In an effort to beat England, Bonaparte started a blockade and importing of sugar was replaced by growing the sugar cane. Haná seemed to be a great area were the sugar was being grown so thanks to sugar cane and of the treadmill the agriculture has unexpectedly increased and the milk production, too. Its oversupply has led to the building cooperative dairies.

3. Wandering for the Olomouc chesse.

The Cheesemakers were transporting the cottage cheese in the tubs called „štandle“ or in the bags from the farmers. Proved by the memories of one cheesemaker from Daskabát, the curricle used to go to the villages in Libavsko all the day and was buying cheese. There were also dealers who were dealing with buying the cottage cheese for bigger producers and they were delivering the cottage cheese for the cheesemakers if their demand of the cottage cheese could not be covered by the production from the location and surroundings. Cottage cheese was often purchased on the markets and later was being imported from the dairies directly to the Tvarůžkárny (Factory of the Olomouc cheese). Cheesemakers gained a large amount of cottage cheese with the same quality and saved the time and the money. The composition of the cottage cheese was gradually changing. To the end of the 19th century, during a few days when milk was kept in wide containers in the cool cellar, the remaining cream was collected with the skimmer and of the cottage cheese was made with the leftovers of milk. Only the expansion of centrifuges for individual farmers and dairies built in the 19th and 20th centuries led to the production of skimmed milk which has less fat, and therefore it changed the cottage cheese. At first the cottage cheese in Olomouc cheese factory was weight up to decise how much salt is needed. It is 3.5 to 4 kg of salt for 100 kg in winter and 5kg in summer. More salted cheese ripens slowly.

4. Tužák or Šráček

The czech word “Tužák” means the water evaporates from the cottage cheese and it becomes resistent and resilient. These were the necessary qualities the cottage cheese needed to have to be turned into the Olomouc cheese. And everything mentioned above was achieved in “Tužák”, poetically called “Šráček” in Haná. The basis of Šráček were two boards or board and ladder, between between which the fresh cottage cheese was saved in a cloth bag. When the upper board was burdened, the cottage cheese lost the water. The size of Šráček was given by the measure of the cottage cheese. It means 5 kg or for example 50 kg. The whole equipment was made of wood and the workers had to monitor that the cottage cheese didn’t meet with the metal. In the Olomouc cheese factory Šráček was not often used tool, its own production of cottage cheese is much more known.

5. And what to do with the cottage cheese?

The cottage cheese was lying in the lower barrels for from one to three days, where it was mixed with the salt. Later, with the succession of the cottage cheese mills the cottage cheese was salt after the first, more frequently after the second grinding (it was sometimes grinded 4 times) to ensure there were no lumps on the cottage cheese. Originally the smaller amount of cottage cheese was processed with kneading hands, but the most common procedure remained pedaling with the bared and well washed feet. Two wenches or one man were pedalling the 30 cm high layer of cottage cheese in the low barrels from one and a half to two hours. Pedaling is rarely documented in the 30s of the 20th century by small producers, for example in Luká and in Loštice. In the mechanical production of the Olomouc cheese the cottage cheese was knead by turning screw, which pushed the mass of cottage cheese into the molding machine. Cottage cheese which was not turned to the Olomouc cheese during a few days was saved in the barrels or later in to the concrete tanks. Drilled holes were in the barrels at a distance of approximately 20 cm from the bottom to allow the whey to flow out. For the same reason the worksheet with groove was saved in the botton of the concrete pools. The fresh and stored cottage cheese was usually mixed for molding.

6. Time of pattering and clattering.

For forming of the future Olomouc cheese, pattering is the oldest technique and it sporadically retained till the first decades of the 20th century. From the ball of cottage cheese the future form of the Olomouc cheese was originated by pressing between palms. It is said good ,,Pleskačka“ (the woman, who was working with the Olomouc cheese) produced 50-70 heaps of the Olomouc cheese and the best produced up to 100 heaps - about 6000 pieces. A novelty in the early 20th century was a clatter made of two cylinders connected with iron hinges. The lower roller was attached to the board, the component of the upper roller was the wooden handle. Both rollers were turning on the interface so that when embed cottage cheese was pressed - formed - corresponding to the desired size of the Olomouc cheese. Average daily output of pleskačka with clatter reached 150 heaps, that means 9000 pieces. Moulding machines could produce up to 10,000 pieces per hour. Karel Pivný had no doubts about the mechanical production, he was a successor and son-in-law of Alois Wessels. Karel Pivný and his wife Františka purchased the molding machine around 1924 in Germany. It was the first documented molding machine for producing the Olomouc cheese.

7. Olomouc cheese was drying on the sun and on the stoves.

When the future cheese got their form, they were storing on the ,,šindle“, thin, not planed boards with dimensions of approximately 130 x 25 and thickness around 1 cm. ,,Šindele“ were adapted to the size of „dryer“ and after machine production the dimensions were unified. Not planed ,,šindele“ prevented cheese before slipping. Originally the cheese was dried on the sun. On every ,,Šindel“ one heap (60 pieces) of cheese was put. They were stocking into the ,,Dary“. Dary are simple racks which are strongly attached into the wall. Later in the large-scale they were replaced by the roadworthy,,Dary“. During drying ,,šindele“ were arranged in ,,dary“ the way the top was put down and the bottom was put up, that the whole batch was drying periodically. Drying was the most sensitive part of the production compared to pedaling which the most labourious part. It was beginning of drying at a lower temperature and the end of the drying was at a temperature 30-35 degrees Celsius in 1-2 days. If drying was too quick, Olomouc cheese stay tough, crumbled and had an undesirable color (turning in the blue, black color). On the other hand, badly dried cheese was smeared.

8. Washing or Bathing.

Correctly dried Olomouc cheese was washed - bathed – and manually sprinkled in the bath, tubs or similar containers from the ,,šindel“. There were washed in the salt water,possibly in the whey after sweet cheeses. They were slowly agitated by hands and were divided apart. At the large-scale large machinery powered washers with a rotating cylinder were used. During washing, the most of the Olomouc cheese were fractured and damaged then they were processed to the cheese fault ,,Kóske“. Casually formed Kósky were very popular and affordable in taste and they were cheaper than classic Olomouc cheese. It was grateful goods for the Olomouc cheese peddlers and childreb were going to the Olomouc cheese factory for “Bakolo” when their mother did not know what to cook for dinner.

9. Straightening and maturation.

After washing Olomouc cheese was loosely toss into boxes - ,,kisten“ - with a perforated bottom or more often with the cut corners to allow water to drain off. Boxes with the washed Olomouc cheese were stack into the cellar, where the Olomouc cheese makers were“tossing„ them every two days. Then the cheese was stack cross on each other and the size of the left gap determined the speed of maturation. The upper box was covered by the lid. After swapping the upper boxes were given down and vice versa - because of the uniform maturation. After the third swapping most Olomouc cheese already had characteristic yellowish color. After the last swapping the Olomouc cheese in boxes was composed abreast to the horizontal cylinders or to the standing chunks usually into five rounds. Rollers were also rearranging during the maturation into the chunks. Olomouc cheese were continuously guarding because of the „evaporating“ and every second or third day had to be rearranged so that the middle cheese came to the edge, where maturing was faster.

10. How the Olomouc cheese was prepared for the road.

Originally the Olomouc cheese was freely composed to the returnable boxes of solid plates. The development of the production and the trade on the turn of the 19th and 20th century led to producing lightweight, disposable boxes of rectangular shape usually, used till these days. Since the sixties of the 20th century the boxes were appearing in the combination of the wood and the pasteboard and then only the pasteboard. Loosely folding of the Olomouc cheese was improved around the year 1900 with unloading boxes with stiff parchment paper. Packaging of individual chunks or chunk pairs in parchment was extended from the twenties and ten years later the Olomouc cheese was packed to the cellophane. The packaging techniques include small boxes or jars of wax paper or plastic for the fault of the Olomouc cheese in other words ,,Kóske“. Parchment paper and especially cellophane was closed by the sticker.

11. Olomouc cheese goes to the world.

Oloumouc markets and Olomouc dealers considerably contributed to the trade with Olomouc cheese. Formans became the first carriers of large amount of the Olomouc cheese and in the bigger distances who were also selling Olomouc cheese during their way to their target destination. Rapid construction of railways in the last decades of the 19th century brought new options for the Olomouc cheese. Basket on the back was an universal assistant of small producers. The reports of other facilities are known, too. Imports of the Olomouc cheese from Topolany to Brno are documented around 1840. Wheelbarrow is maintained as a popular means of transport and later it was used for transporting the Olomouc cheese to the station or was used by small sellers for distribution around the area. When the use of bicycles icreased – became more affordable – the Olomouc cheese makers started to use bicycles. Small dealers were cycling for the goods to the Olomouc cheese factory. A carriage was permanently used for delivery in the wider area. The post became a popular method of transportation. Cars which were mainly used by bigger dealers brought the intervention to the traditional distribution. They made a similar procedure as well as smaller manufacturers, for which purchase cars were sometimes beyond their capabilities. Bigger dealers constrained smaller dealers to used this procedure, for whose were car purchase byond their options. The intervention into the traditional division of travel means was broght by cars, which were mainly used by bigger producers and it forced smaller producers to purchase a car even if they were not able to pay for it. But the cars were a symbol of the modern times, too.

12. Sale of Olomouc cheese

There are thousands of ways and places where and how to sell cheese curds, but only one way and one place are the best – to go through the Museum of Olomouc cheese curds and at the end of the road enter the brightly lit shop of cheese curds by A. W. Loštice, spol. s.r.o.

Only a few hundred meters…

And rather one more time…

There are thousands of ways and places where and how to sell cheese curds, but only one way and one place are the best – to go through the Museum of Olomouc cheese curds and at the end of the road enter the brightly lit shop of cheese curds by A. W. Loštice, spol. s.r.o.

Only a few hundred meters…

You may already be starting to smell that unique scent from afar… and you're already on your way, dear visitors, you can't miss the store…

but …. you will get the best Olomouc cheese in the company shop A.W. where our museum tour ends.