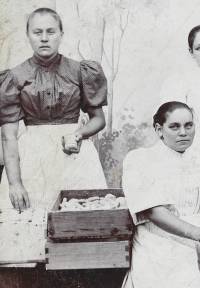

Kitchen – everything had its beginning here

At first the curd cheese was shaped from a piece of curd by its flattening between palms. Later on, a wooden mould and finally the moulding machine was used. The cheese was then dried on the boards inserted in racks. Followed by cheese washing and storing in boxes, where ripening was commenced. The nearly ripened curd cheese pieces were stacked in the boxes in vertical blocks. Final ripening took place here …