Obsah

2. Curd and dexterity

2.1. In the beginning there was curd

The curd was bought at markets or in peasant dairies. It was mainly transported in barrels and barrows. The most strenuous work involved in making tvarůžky was kneading the curd (by hand or by treading the curd with bare feet). Try it yourself on our treadle machine. Curd mills - hand-powered and then machine-powered - expanded rapidly from the early 20th century onwards. Good curds and good workmanship were the basis of success…

2.2. Kitchen – this is where it all began

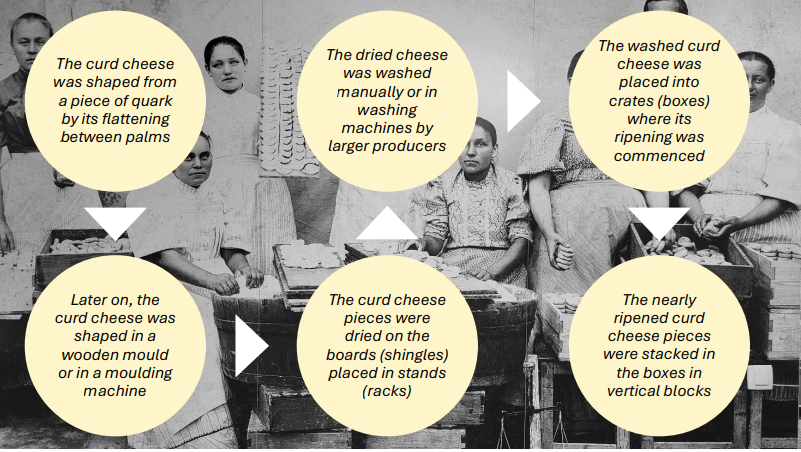

Originally, tvarůžky were formed from a piece of curd by pressing it between the palms. Later, with a wooden flap and finally by machine. They were then dried on boards placed in racks. The cheeses were then washed and placed in crates, where they began to ripen. The almost ripe tvarůžky were folded (rolled) in the crates into standing blocks. Here they ripened…

„Za pecó“ or „behind the oven“ - that is, by drying tvarůžky over a tiled stove or perhaps even over an old bread oven - the successful production of Josef Wessels began. Alois Wessels expanded production many times over and became permanently the largest producer of tvarůžky. The actual production was divided into five parts: moulding – drying – washing – ripening – stacking.